Granda Machine

The leaner, smarter, faster way to produce different types of products.

– Engineered to Different Standards Accordingly

– Handle Tough-to-run Materials With Ease

– Highly Automated & Labor-free

Your Manufacturing Made Easy

With Granda's Machines

-Join hundreds of Granda’s happy customers to produce quality cosmetics with minimum downtime.

- Manufactured to cGmp norm using 304/316 stainless steel

- Engineered to Pharma standards to avoid cross-contamination after each formula change-over

- Built-in quality control system to detect and reject inferior outputs (optional function)

Maximized Capacity Utilization

- Operation rate > 95%

- Non-stop production achieved by auto material feeding system & continuous product delivery to filling system

- Branded HMI featuring up to 20 programmed product recipe

- High Efficient tanks & pipe lines cleaning

Greater Product Versatility

- Handle tough-to-run various packages with ease: jars, bottles, dropper bottles with flat/square/round and other irregular shapes

- A broad range of package sizes, counts are adjustable directly on touch screen

- Able to meet fast-changing market demand

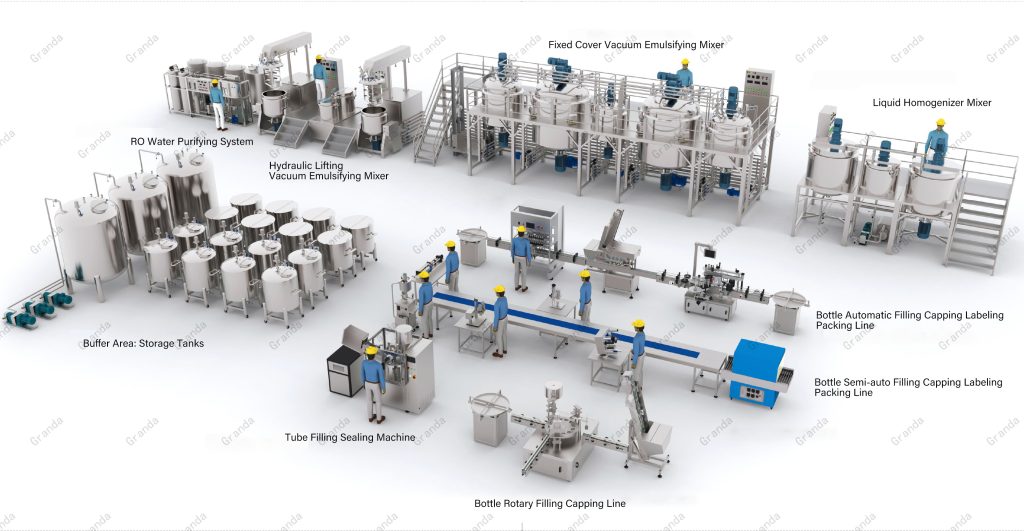

How are cosmetics/food/pharmaceutical made?

A typical manufacturing process

–What are the machines required for each production process

What Types of Machines Does Granda Provide?

Granda manufactures various of cosmetics/daily chemical/food/pharmaceutical machines for different applications you can find on the market.

Single Stage RO Water Purifier – for dinking / daily chemical / food

Double Stage RO Water Purifier – for cosmetics

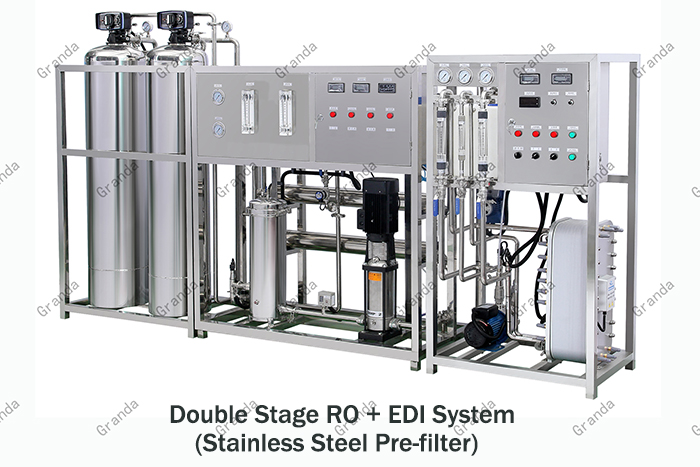

Double Stage RO Water Purifying + EDI System – for phamaceutical / perfume

Machine Details

Single Stage RO Water Purifying System

- Application: Drinking water, liquid wash produts, food products, etc.

- Conductivity of purified water: ≤10us/cm (based on raw water conductivity ≤300us/cm)

- Capacity: 500L/hour to 20,000L/hour (customized)

- Voltage: 380V/50Hz/Three Phase (customized)

- Pre-treatment housing material: Stainless steel or glass fiber optional

- Pre-treatment Filter: Quartz sand, Active carbon & Softener

- RO Membrane: CSM from Korea or DOW from the US.

- Recovery rate: 50%

Desalting rate: 98%-99.5%

Double Stage RO Water Purifying System

- Application: cosmetics production, boiler water, etc.

- Conductivity of purified water: 2-3us/cm (based on raw water conductivity ≤300us/cm)

- Capacity: 500L/hour to 20,000L/hour (customized)

- Voltage: 380V/50Hz/Three Phase (customized)

- Pre-treatment housing material: Stainless steel or glass fiber optional

- Pre-treatment Filter: Quartz sand, Active carbon & Softener

- RO Membrane: CSM from Korea or DOW from the US.

- Recovery rate: 25%

Desalting rate: 98%-99.5%

Double Stage RO + EDI System

- Application: Electronic industry, pharmaceutical industry, perfume production, etc..

- Conductivity of purified water: ≤0.5us/cm (based on raw water conductivity ≤300us/cm)

- Capacity: 500L/hour to 20,000L/hour (customized)

- Voltage: 380V/50Hz/Three Phase (customized)

- Pre-treatment housing material: Stainless steel or glass fiber optional

- Pre-treatment Filter: Quartz sand, Active carbon & Softener

- RO Membrane: CSM from Korea or DOW from the US.

- Recovery rate: 25%

Desalting rate: 98%-99.5%

Model Comparison

| Model No. | Productivity (T/H) | Motor Power (kw) | Recovery Rate (%) | Outlet water conductivity (us/CM) | Raw Water Conductivity (us/CM) |

| GO-500L | 0.5 | 1.5 | 50 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.5us/cm | ≤300 |

| GO-1000L | 1 | 2.2 | 50 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.6us/cm | ≤300 |

| GO-2000L | 2 | 3 | 50-60 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.7us/cm | ≤300 |

| GO-3000L | 3 | 4.5 | 55-65 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.8us/cm | ≤300 |

| GO-4000L | 4 | 6.5 | 55-65 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.9us/cm | ≤300 |

| GO-5000L | 5 | 8 | 60-70 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.10us/cm | ≤300 |

| GO-10000L | 10 | 15 | 60-70 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.11us/cm | ≤300 |

| GO-20000L | 20 | 22 | 65-75 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.12us/cm | ≤300 |

| GO-30000L | 30 | 26 | 70-75 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.13us/cm | ≤300 |

| GO-50000L | 50 | 55 | 70-75 | Single stage ≤10us/cm; double stage 2-3us/cm; EDI ≤0.14us/cm | ≤300 |

Machine Details

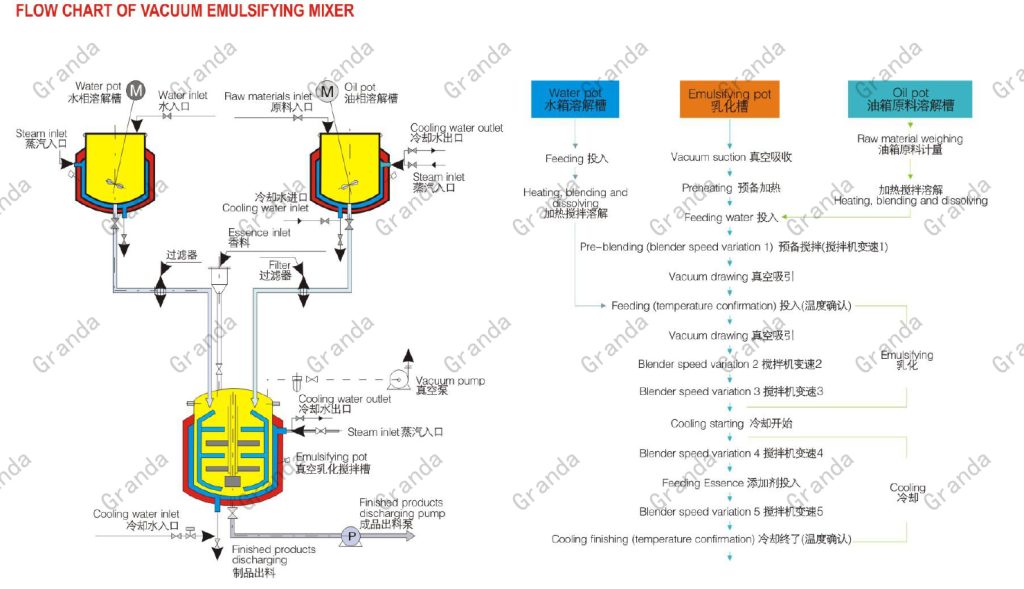

Hydraulic Lifting Vacuum Emulsifying Mixer

- Application: High viscosity liquid, cream, ointment, ketchup sauce, mayonnaise, hair dye, etc.

- Capacity: 5L – 1000L (customized)

- Voltage: 380V/50Hz/Three Phase (customized)

- More types: plane layout can be customized by personal requirementaccording to the factories of customers, can supply the single cylinder/double cylinder lifting/vertical, and also can supply the small type of emulsifyingmachine for the labs;

- More functions: support the manual operation, PLC human-computer interfaceoperation, the highest vacuum degree can be reached to -0.095MPA;

- More supporting: Can be selected the CIP/SlP system and error preventionsystem, which can completely make sure the security of the products;

- More options: The homogeneity can be divided into upper and underhomogeneity and external circulation structure, the stir can be divided into one-way and two-way screwing stir;

- More requirements: configuration requirements can be divided into thestandard configuration and imported configuration, such as the frequency converter,motor,electric appliance and so on.

Fixed Cover Vacuum Emulsifying Mixer

- Application: High viscosity liquid, cream, ointment, ketchup sauce, mayonnaise, hair dye, etc.

- Capacity: 100L – 20,000L (customized)

- Voltage: 380V/50Hz/Three Phase (customized)

- Mixer: customized to one-way or two-direction mixing

- Homogenizer: customized to bottom homogenizer, upper homogenizer, upper+bottom homogenizer and external homogenizer, etc.

- Control system: button control or PLC touch screen control optional

- Advantages of fixed cover design: large capacity, easy to fit in factory layout, more affordable price, all-in-one control, etc.

Model Comparison

| Model | Effective Capacity | Emulsifier | Agitator | Vacuum pump | electirc Heating power | Steam heating pressure | |||

| Liters | KW | RPM | KW | RPM | KW | Limit Vacuum | KW | Mpa | |

| GMV-5L | 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| GMV-10L | 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| GMV-20L | 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| GMV-50L | 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| GMV-100L | 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| GMV-200L | 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| GMV-300L | 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| GMV-500L | 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| GMV-1000L | 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| GMV-2000L | 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam hetaing | 0.2 |

| GMV-5000L | 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters for reference ONLY, all the machines can be customized accordingly. | |||||||||

Machine Details

Liquid Homgenizer Mixer

- Application: Low viscous liquids, liquid soap, shower gel, shampoo, face toner, essential oil, toilet cleanser, etc.

- Capacity: 50L – 20,000L (customized)

- Voltage: 380V/50Hz/Three Phase (customized)

- Frame Material: Stainless steel 304

- Product contact material: stainless steel 316L

- Mixing design: one-way mixer, two-ways mixer optional

- Homogenizer design: optional according to products type and budget

- Layout design: movable or fixed platform optional

Model Comparison

| Model | Effective Capacity | Stirrring power and speed | Homogeneous power and speed | Heating power | |||

| Liters | KW | R/MIN | KW | R/MIN | Electric heating | Steam heating | |

| GPM-50 | 50 | 0.75 | 0-65 | 3 | 3600 | 6 KW | Steam heating energy conservation and environmental protection, selected according to need |

| GPM-100 | 100 | 1.5 | 0-65 | 1.5 | 3600 | 12 KW | |

| GPM-150 | 150 | 1.5 | 0-65 | 1.5 | 3600 | 12 KW | |

| GPM-200 | 200 | 1.5 | 0-65 | 3 | 3600 | 18 KW | |

| GPM-300 | 300 | 1.5 | 0-65 | 3 | 3600 | 18 KW | |

| GPM-500 | 500 | 2.2 | 0-65 | 4 | 3600 | 27 KW | |

| GPM-1000 | 1000 | 4 | 0-65 | 7.5 | 3600 | 36 KW | |

| GPM-1500 | 1500 | 4 | 0-65 | 11 | 3600 | 45 KW | |

| GPM-2000 | 2000 | 5.5 | 0-65 | 11 | 3600 | recommed steam heating | |

| GPM-3000 | 3000 | 7.5 | 0-55 | 15 | 3600 | ||

| GPM-5000 | 5000 | 11 | 0-55 | 22 | 3600 | ||

| The parameters for reference ONLY, all the machines can be customized accordingly. | |||||||

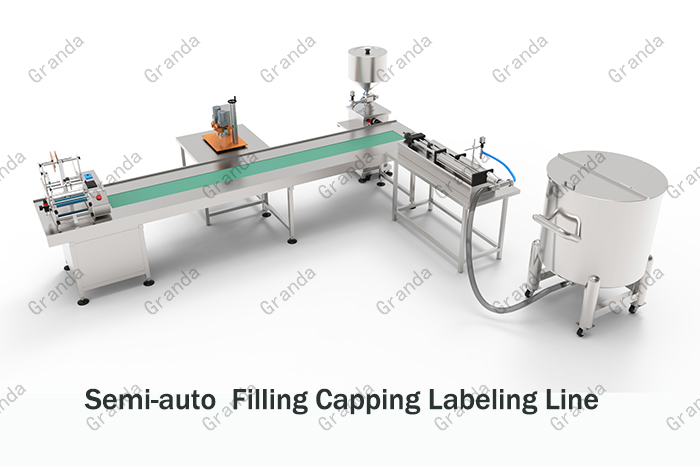

Automatic Bottle Filling Packing Line

Semi-auto Tube Filling Sealing Machine

Tube Filling Sealing & Packaging Line

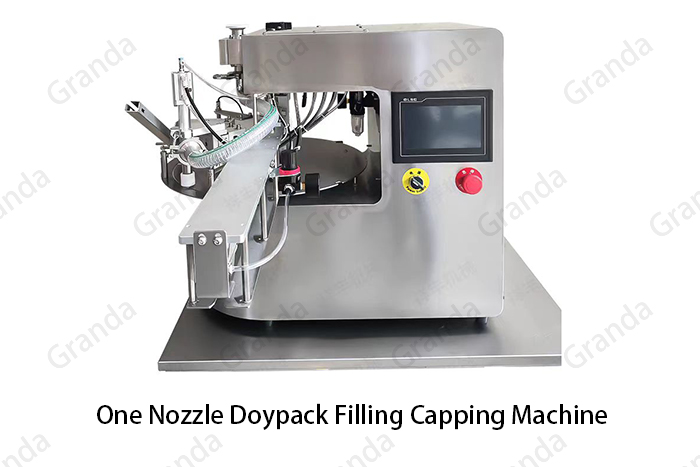

Doypack Filling Capping Machine

Machine Details

Bottle Filling Packing Line

- Application: all types of stand-up containers, bottles, jars, dropper bottles, containers, etc.

- Capacity: customized as per client’s daily output and budget.

- Automation stage: manual, semi automatic, automatic stages as needed.

- Can seperately sell the filling machine, capping machine, or labeling machine.

Tube Filling Sealing Machine & Packaging Line

- Application: Ointment, toothpaste, hair dye, cream, lotion, gel, etc.

- Suitable tubes material: plastic tubes, aluminum tubes, laminated tubes, etc.

- Capacity: customized as per client’s daily output and budgets.

- Automative stage: manual, semi-automatic, automatic types as optional.

Bag Filling Packing Machine

- Application: powder, liquid, semi-liquid, paste, granule, water, etc.

- Applicable packages: plastic bags, doypack, sachet, etc.

- Capacity: customized as per client’s daily output and budgets.

- Automative stage: semi-automatic, automatic types as optional.

Perfume Making Machine

Automatic Perfume Filling Line

Mascara Filling Packing Line

Compact Powder Pressing Machine

Machine Details

Perfume Production Line

- A whole perfume production line combines with: perfume making machine, perfume storage tank, perfume filling – capping – crimping – packaging machine

- Capacity: customized as per customer’s daily output and budget.

- Made of high – quality 304 or 316L stainless steel. The pressure source is a pneumatic diaphragm imported from the US for positive – pressure filtration.

- The connecting pipes are sanitary polished pipes with a quick – install connection for easy assembly, disassembly, and cleaning.

- With a polypropylene microporous filtration film, it’s widely applicable in the cosmetics industry, and laboratories for small – volume liquid clarification, bacteria removal, filtration, or micro – chemical analysis, offering convenience and reliability.

Makeup Production Line

- Makeup products include: lipstick, mascara, foundation, BB cream, eyeliner, eyebrow, loose powder, compact powder, etc.

- Makeup production line includes RO water machine, mixing machine, filling machine, capping machine, labeling machine and packing machine.

- Machines function, daily output, size can be customized accordingly.

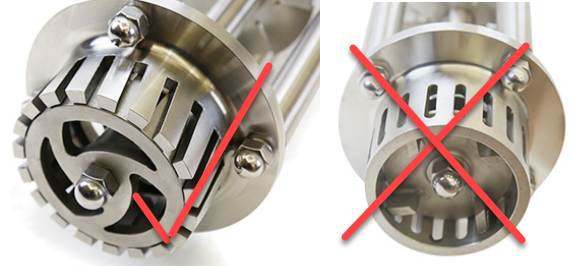

Why Choose Granda Machines?

-Do you know that the quality of a machine could differ so much?

Are You Satisfied With Your Current Machines?

-How much are the problems costing you?

Annoyed With Reject Ratio?

Unhappy With Product Quality?

Machine ls Not Versatile?

Frustrated With Productivity?

Unique Benefits of Owning Dranda's Machine

-We care what you care most about buying a cosmetics machine.

Our vision is to help each client stay at the top of “The Best Manufacturer” List.

Set The Benchmark & Be More Competitive

Reduced Operating Costs

Improved Product Quality

Enhanced Efficiency & Productivity

How Are Granda's Machines Manufactured?

Granda’s cosmetics/food/daily chemical/pharmacuetical machines are all designed, programmed and manufactured in-house.

Let’s take a look at Granda’s workshop and manufacturing process.

Granda Machine- The Ultimate FAQ Guide

Looking for the Right Machine?

Overwhelmed by too many options? Let Granda guide you.

Our FAQ covers everything you need to know about choosing the perfect machine for cosmetics, food, pharmaceuticals, and daily chemicals. Make a smarter, informed decision with Granda.

Start exploring now and find the ideal solution for your production needs!

Table of Contents

1. What industries can Granda machines be applied to?

2. Can Granda machines meet the production needs of different batch sizes?

3. What are the key features of Granda machines for cosmetics production?

4. How does Granda ensure the safety of food production with its machines?

5. What types of pharmaceutical products can Granda machines manufacture?

6. Are Granda machines easy to operate for beginners?

7. How often does a Granda machine need maintenance?

8. What kind of after – sales service does Granda offer?

9. Can Granda machines be customized according to specific production requirements?

10. What safety measures are in place for Granda machines?

11. How does Granda ensure the quality consistency of products produced by its machines?

12. Can Granda machines be integrated into an existing production line?

13. What is the energy consumption of Granda machines?

14. How long does it take to deliver a Granda machine after placing an order?

15. What payment methods does Granda accept?

16. Can Granda machines handle different viscosities of raw materials?

17. What training is provided for operating Granda machines?

18. How does Granda ensure the confidentiality of customers’ production processes?

19. What quality certifications do Granda machines have?

20. Can Granda machines be used for R & D purposes?

21. What is the lifespan of a Granda machine?

22. How does Granda support customers in terms of spare parts supply?

23. Can Granda machines be operated remotely?

24. What is the noise level of Granda machines during operation?

25. How does Granda handle customer complaints?

26. Can Granda machines be upgraded with the latest technology?

27. What are the transportation options for Granda machines?

1. What industries can Granda machines be applied to?

- Can Granda machines meet the production needs of different batch sizes?

- What are the key features of Granda machines for cosmetics production?

- How does Granda ensure the safety of food production with its machines?

- What types of pharmaceutical products can Granda machines manufacture?

- Are Granda machines easy to operate for beginners?

- How often does a Granda machine need maintenance?

- What kind of after – sales service does Granda offer?

- Can Granda machines be customized according to specific production requirements?

- What safety measures are in place for Granda machines?

- How does Granda ensure the quality consistency of products produced by its machines?

- Can Granda machines be integrated into an existing production line?

- What is the energy consumption of Granda machines?

- How long does it take to deliver a Granda machine after placing an order?

- What payment methods does Granda accept?

- Can Granda machines handle different viscosities of raw materials?

- What training is provided for operating Granda machines?

- How does Granda ensure the confidentiality of customers’ production processes?

- What quality certifications do Granda machines have?

- Can Granda machines be used for R & D purposes?

- What is the lifespan of a Granda machine?

- How does Granda support customers in terms of spare parts supply?

- Can Granda machines be operated remotely?

- What is the noise level of Granda machines during operation?

- How does Granda handle customer complaints?

- Can Granda machines be upgraded with the latest technology?

- What are the transportation options for Granda machines?

Still got questions? Call, email or, chat, today!

Get Your Quote Today!

Let us help you choose the right machines.

Contact a product specialist to identify the right machine solution for your application, please give us a call +86-13719498645 or email our expert at gdmachine@aliyun.com to get a guidance today.