GRANDA Machines Catalogue

Get All Your Need from One Stop

Equipment from A to Z

for A Complete Cosmetics/Food/Pharmaceutical Manufacturing Process

You’re probably here because you just venture into in-house cosmetics/food/pharmaceutical production and you need more than a trusted machine manufacturer to provide all equipment from A to Z for a complete manufacturing process.

You will also be thrilled if you could be guided by an expert every step of the way, to make sure your investment a big success.

You might have been sold machines that did not live up to expectations, and in order to satisfy sophisticated consumer market & stay constantly competitive, you are desperately looking for more efficient & versatile machines to produce all types of your products cheaper and faster than your competitors.

Either way, you are landing on the right page.

GRANDA is here to help.

Built for All Types of Applications

– GRANDA customizes & manufactures all types of machines for cosmetics/food/pharmaceutical products you can find on the market.

Select By Products

Foundation / Lipstick / Mascara / Powder, etc

Cream / Lotion / Toner / Essential Oil, etc

Shampoo / Detergent / Liquid Soap / Shower Gel, etc

Ointment / Paste / Balm, etc

Perfume / Fragrant wood, etc

Mayonnaise / Sauce / Paste, etc

Select By Packages

Different bottles / jars & caps

Plastic tube / aluminum tube, laminate tube

Mascara / lipgloss / lip glaze tubes

Pressed powder / loose powder, etc

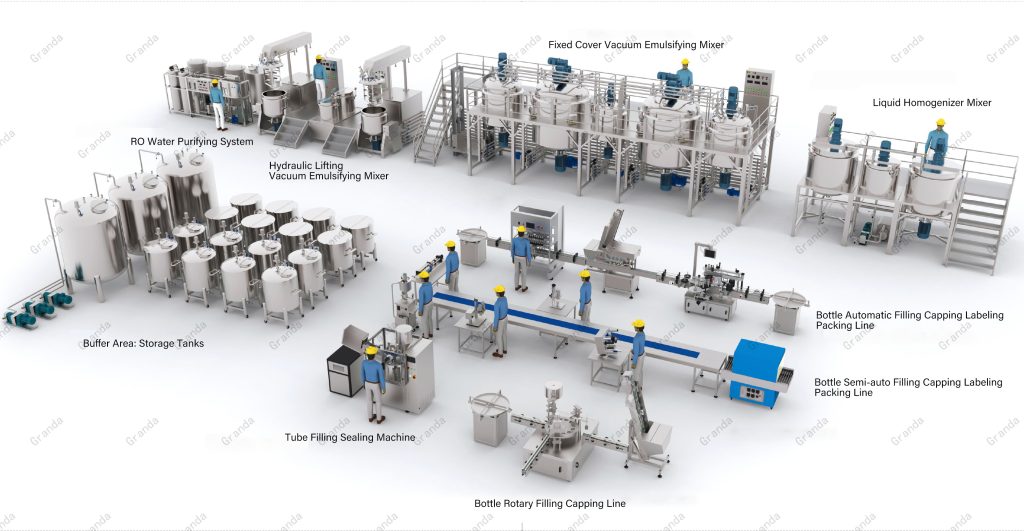

Select By Work Flow

-19-300x169.jpg)

Equipment for A Complete Manufacturing Process

What is a complete cosmetics/food/pharmaceutical manufacturing process ?- How are cosmetics made (or food / pharmaceutical?

A complete cosmetics manufacturing process entails the following 5 steps:

Step 1: RO Water Purification Process

Step 2: Product Preparation Process

Step 3: Filling & Packaging Process

Step 4(Optional): Outer Box Secondary Packaging Process

Step 5: End-Of-The-Line Packaging Process

GRANDA provides Turn-key production line and equipment required in each step manufacturing process as follows:

Step1: RO Water Purification Process

The water used in making cosmetics/food/pharmaceutical has to be purified for different standards that exclude of bacterials, fungus, coliform, impurities, heavy metals, particles and mote.

“Tap water, well water, spring water, mineral water.. Can any of these water be used to make my products?”

The answer is a sure “NO”. They have to be filtered until all the impurities and bacterials are removed.

By saying so, getting purified water in place is the first step towards making a high quality products. That is where a good water purification equipment comes in.

Step 2 : Product Preparation Process

Following water purification process comes product preparation process.

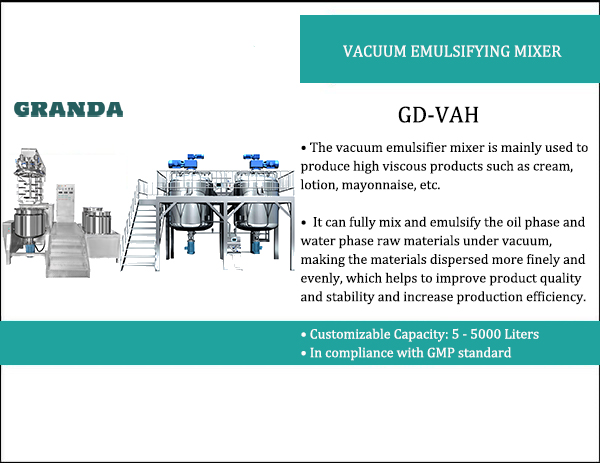

In this step, the production equipment would be different according to products state — high viscous or low viscous.

Regards low-viscous liquid products (oil, detergent, liquid soap, etc), water tanks with mixing function are required.

Regards high-viscous liquid products (cream, paste, gel, lotion, etc), the mixing tank with homogenizing + heating + vacuum functions are needed.

Purified water that comes from previous water treatment process is to be mixed with other chemical ingredients and fragrance in the mixing tank, then processed until the ingredients are completely dissolved.

The cosmetics/food/pharmaceutical products are hence in place, ready to be transferred to filling packing line to fill into the packages.

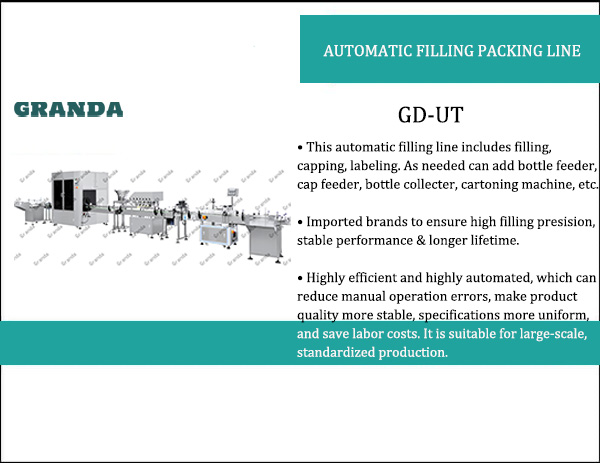

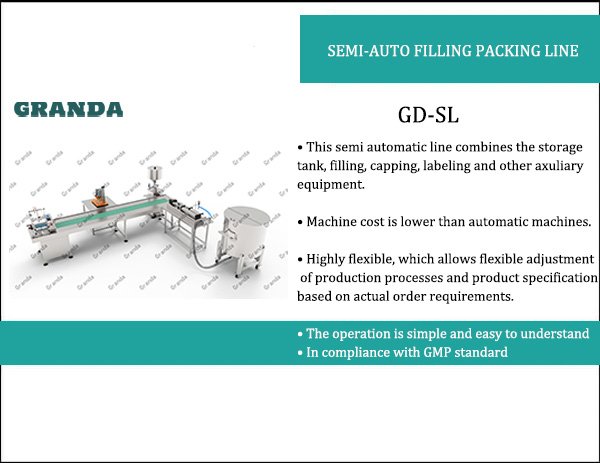

Step 3 : Filling & Packaging Process

Filling and packaging process are different according to packages type, most processes of cosmetics/food/pharmaceutical products typically involves following steps:

1). Bottles/Jars/Container: Products feeding into filling machine – Products filling into bottles/jars – feeding caps on bottles/jars – caps closing – labeling – batch code printing – packing bottles/jars into box – plastic sealing – carton box packaging

2). Tubes: Products feeding into machine hopper – orientation mark – filling products into tubes – tube tail sealing – cartoning machine to pack tubes into box – batch code printing – finish package

3). Other irregular packages: such as plastic bags, powder package, small tubes, should be customized in different machines and process accordingly.

This process applies to the manufacturing of all types of liquid products for various application on the market : Face Cream, Eye Cream, Ointment, Essential Oil, Face Toner, Shampoo, Shower Gel, Liquid Soap, Detergent, Toilet Cleansing, Mayonnaise, Kethup, Sauce, Toothpaste, Facial Mask, etc.

What differs from each production line machine used in this process are primarily the machine speed, the applications such as products viscosity, package size, package design, etc.

Filling & Packing Line for Bottles / Jars / Containers

Check your packages samples at hand, if they are containers that can stand up, this filling packaging line is right for you.

Tube Filling Sealing Line

Check your package samples at hand. If the package is soft tube with sealing tail (plastic sealing or metal folding sealing), it is made by the tube filling sealing machine.

Step 4 (Optional): Secondary Packaging Process

The majority of daily chemical / food products on the market are sold as individual package.

But most cosmetics / pharmaceutical products are packed in small carton box with plastic film outside the box.

It is either done by manual packing or the Cartoning Machine & Plastic Packing machine

If your products are without outer box, or you prefer pack them by manual, this process can be skipped.

Step 5 : End-of-Line Packaging Process

End-of-line packing process refers to case packing and palletizing process.The process may be completed semi-automatically by manual or fully automatically with the use of case packer and palletizer, depending on the setup, budget and needs of the production facility.

Semi-automatic Case packing process traditionally entails a lot of labor works to put product packages into each carton, often in a less effective way.

With the help of an automated case packing machine and palletizer, labor crunch and soaring labor costs are no more headaches.This end-of-line automation is critical in large-scale production environments because it enhances efficiency, reduces labor costs, and minimizes handling errors.

A case packer in cosmetics/food/pharmaceutical production is a type of automated machine used to pack the individually wrapped or packaged products into larger boxes or cases for distribution and sale.

Case packers can vary in complexity from semi-automatic to fully automatic systems. They handle tasks such as forming the case or box, filling it with a precise number of packages, and then sealing the case for shipment.

A palletizer in the context of cosmetics/food/pharmaceutical production is a machine used to automate the process of stacking and organizing finished packages onto pallets for shipping and storage.

The palletizer typically picks up the packages from the production line, organizes them in a predetermined pattern, and stacks them neatly on a pallet.

Trusted by Happy Customers in Over 50+ Countries

Global customers love GRANDA’s high performance cosmetics/food/pharmaceutical machine.

Opt for GRANDA, Be happy as they are!

Direct Sales from Machinery Manufacturer

All of GRANDA’s production lines are designed, programed and manufactured in-house.

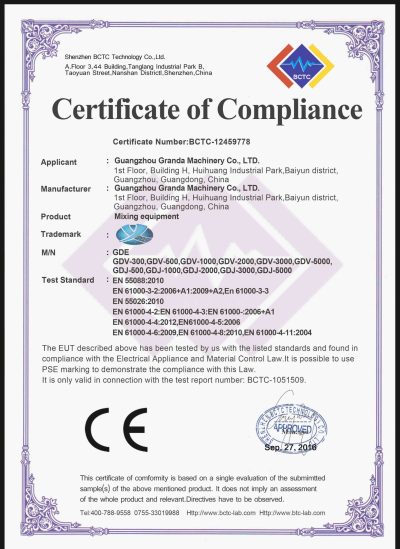

Certificates

All of Granda’s production line machines are engineered to European CE safety compliance and confirming GMP standard as highest safety design.

Buying Tips

From Cosmetics Contract Manufacturers to Brand Owners: How to Choose Cosmetics Machines

1.Understand Production Requirements

1). Production Volume: Brand owners and contract manufacturers first need to assess their production scale.

For small scale production or brand new startups with limited initial orders, compact and semi – automatic machines are cost-effective. They are easier to operate and maintain, and the investment cost is relatively low.

For large – scale contract manufacturers handling multiple brand orders, high speed, fully automatic machines are essential to meet large – volume production demands, reducing labor costs and increasing production efficiency.

2). Product Range: Different cosmetics products require different machines. For example, making liquid foundation needs machines with precise liquid – filling and mixing functions. Lipstick production demands machines that can accurately shape and fill the lipstick bullets.

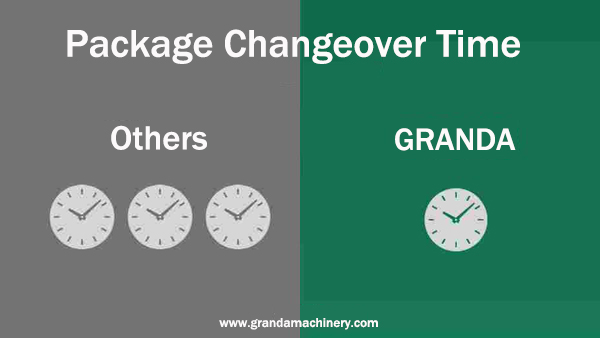

If a brand plans to launch a diverse range of products, they should choose machines with multi – function capabilities or be able to be easily reconfigured for different production needs.

2. Cost - Benefit Analysis

1). Initial Investment: Compare the prices of different machines in the market. However, do not solely base the decision on the lowest price. Sometimes, a slightly higher priced machine with better quality and performance can bring long – term cost savings in terms of reduced maintenance and higher production efficiency.

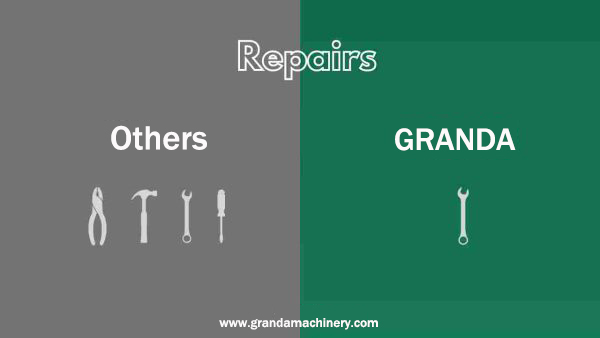

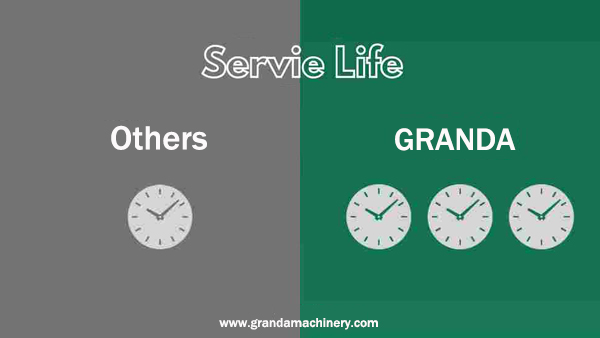

2). Total Cost of Ownership: Consider the long term costs, including energy consumption, maintenance, and potential upgrades. A machine with low initial cost but high long term costs may not be the best choice. Calculate the total cost of ownership over the expected service life of the machine to make a more informed decision.

3. Supplier Reputation and After - sales Service

1). Supplier Professionalism or Reputation: A reliable supplier is more likely to provide high quality products and professional services.

2). After – sales Support: Ensure that the supplier offers comprehensive after-sales service, including spare part availability, on-site maintenance, and operator training. Quick response to machine malfunctions can minimize production downtime and losses.

Ready to Get A Quote Today?

You will get the machine quote & FREE factory layout design within 4 hours.